Is your air conditioner having a hard time keeping you cool? The problem might be a faulty compressor. Since the compressor is the heart of your AC system, it’s essential for keeping your home comfortable.

When it fails, your entire cooling system can stop working. If you’ve noticed warm air coming from the vents, strange noises, or a sudden spike in your energy bills, it could be a sign of compressor trouble.

In this blog, you’ll explore the most common compressor issues and learn how to fix them so your home stays cool and comfortable again.

Key Takeaways:

The compressor keeps the refrigerant moving through the system, helping your AC cool efficiently.

Be alert for signs such as warm air, strange noises, short cycling, rising energy bills, or a unit that doesn't respond when turned on, as these often point to compressor trouble.

Electrical issues, refrigerant leaks, overheating, dirty parts, or even poor installation can cause the compressor to fail over time.

Faulty capacitor can often be repaired, but if the compressor has serious internal damage, replacement is usually the best solution.

Simple steps like regular cleaning, scheduling professional tune-ups, and fixing small problems early can extend your compressor’s life and save you from expensive repairs later.

What is an Air Conditioner Compressor?

The air conditioner compressor is the heart of the cooling system. It keeps everything running smoothly by circulating refrigerant throughout the unit. Think of it as a powerful pump that pressurizes and moves the refrigerant, helping the system cool the air efficiently. Without it, an air conditioner simply wouldn’t work.

How Does an Air Conditioner Compressor Work?

The compressor’s primary function is to take in low-pressure refrigerant gas and compress it to a higher pressure. This kicks off the cooling process. Here’s how it happens step by step:

Compression: The compressor pulls in low-pressure refrigerant gas from the evaporator coils inside your indoor unit.

Pressure and Temperature Rise: Inside the compressor, the gas is squeezed tightly. This increases both its pressure and temperature.

Movement to Condenser Coils: The now-hot, high-pressure gas moves to the condenser coils outside your home.

Cooling Down: As refrigerant moves through the condenser coils, it gives off heat to the surrounding air and cools, turning into a high-pressure liquid.

Cycle Repeats: The cooled refrigerant flows through an expansion valve, where it cools even more before entering the evaporator coils again. There, it absorbs heat from the indoor air, and the whole cycle starts over.

A clear understanding of how an air conditioner compressor works can help you recognize when it’s not working properly.

5 Warning Signs Your AC Compressor Is Failing

If your air conditioner isn’t cooling like it used to or is making strange noises, your compressor might be in trouble. When it starts to fail, your entire cooling system can suffer.

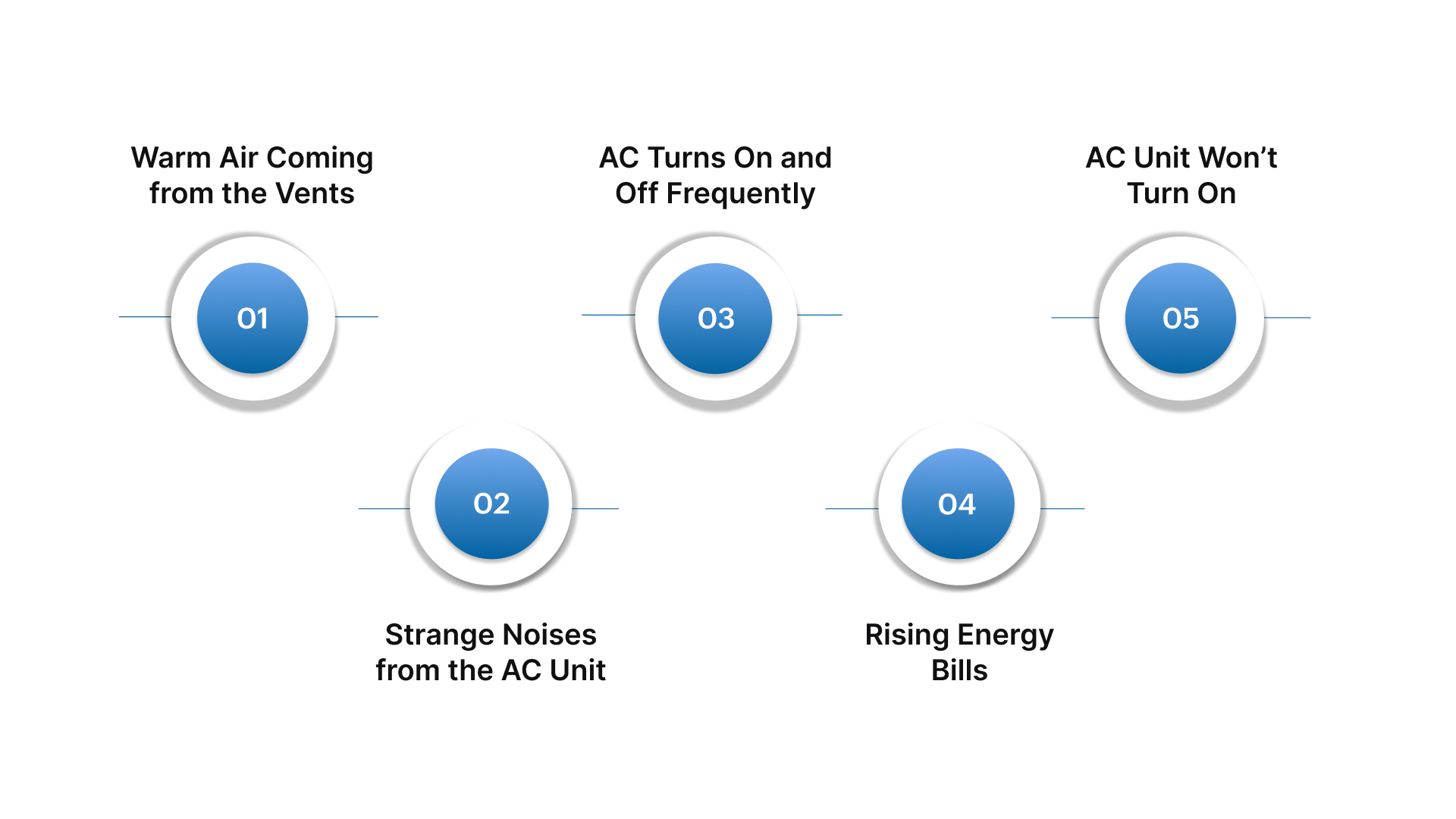

Knowing the warning signs early saves you from expensive repairs or a sudden breakdown in the middle of summer. Here are five signs to watch out for.

Warm Air Coming from the Vents

If your AC is running but the air feels warm instead of cool, it’s usually a sign that your compressor isn’t working properly. The compressor is supposed to circulate refrigerant to cool the air, but when it fails, the system can’t complete the cooling cycle.

Strange Noises from the AC Unit

Hearing odd sounds like buzzing, clanking, or grinding from your AC? That’s often a warning that something’s wrong with the compressor. A loud hum could mean the motor is overworking, while grinding sounds might point to internal damage or debris inside.

AC Turns On and Off Frequently (Short Cycling)

When your AC keeps switching on and off too often, it’s called short cycling. This usually means the compressor is struggling to keep a steady cooling rhythm.

Rising Energy Bills

If your electricity bill suddenly jumps even though your usage hasn’t changed, your compressor might be the culprit. A weak or failing compressor forces the system to work harder to maintain the set temperature, resulting in higher energy use.

AC Unit Won’t Turn On

When your air conditioner won’t start at all, a faulty compressor could be to blame. It might be completely damaged, or there could be a serious electrical issue preventing it from running.

Once you recognize the warning signs of a failing AC compressor, you can better understand what might be causing the issues.

12 Common Causes of AC Compressor Failures

Your AC compressor doesn’t just fail overnight; the problems build up slowly. Knowing what causes compressor failure can help you catch problems early before they turn into expensive repairs or full replacements. Here are 12 common reasons why AC compressors fail and how each one can lead to trouble:

Electrical Issues

Power surges, faulty wiring, or damaged electrical components can seriously affect your compressor’s performance. If it doesn’t get steady power, the motor can overheat, short-circuit, or even burn out completely.

Low Refrigerant Levels

When your system doesn’t have enough refrigerant, the compressor has to work much harder to cool the air. This extra effort creates more heat and pressure inside, which can cause the compressor to overheat or fail.

Refrigerant Leaks

If refrigerant leaks out through cracks or worn seals, the compressor won’t have enough fluid to operate properly. Without the right amount of refrigerant, it can’t stay cool, leading to overheating and damage.

Overheating

Overheating is one of the most common reasons compressors fail. Blocked airflow, dirty coils, or a malfunctioning fan can all cause the compressor to run too hot. When this happens repeatedly, it puts extreme stress on the system and can lead to early failure.

Aging and Wear

Like any mechanical part, compressors wear out over time. Bearings, seals, and motors gradually lose efficiency, especially if the unit isn’t well-maintained. As the compressor ages, it becomes more prone to breakdowns and eventually stops working altogether.

Improper Installation

If your AC system wasn’t installed correctly, the compressor might be under constant strain. Issues like the wrong unit size, poor connections, or incorrect placement can cause it to overwork.

Capacitor Failure

The capacitor gives the compressor motor the energy boost it needs to start. When the capacitor fails, the compressor may struggle to start or might not start at all. It’s one of the most common electrical issues that can lead to sudden compressor failure.

Dirty Air Filters

When filters are clogged with dust and debris, air can’t flow freely through the system. That means the compressor has to work harder to keep your home cool. Over time, this added strain can cause overheating and shorten the compressor’s lifespan.

Blocked Condenser Coils

Condenser coils release heat from the refrigerant. But when these coils get dirty or covered in debris, the heat can’t escape. This forces the compressor to run hotter and harder, which often leads to long-term damage or failure if not cleaned regularly.

Incorrect Voltage

Your compressor motor needs the right voltage to run efficiently. Too much or too little power can cause it to overheat or struggle to start. Faulty wiring, power supply issues, or electrical imbalances are often the root cause of voltage problems.

Faulty Start Relay

The start relay’s job is to send power to the compressor motor when it’s time to start. If the relay fails, the compressor might not turn on, or it might start and stop erratically. Repeated failed starts can wear out the motor quickly and cause permanent damage.

Poor Maintenance

Neglecting regular maintenance is one of the top reasons compressors fail. Skipping cleanings, not checking refrigerant levels, or ignoring small problems can lead to big issues down the road.

Knowing the common causes of AC compressor failures can help you determine whether your unit can be repaired or needs replacement.

How to Know if Your AC Compressor Can Be Repaired?

When the AC compressor stops working, the first thought is often to replace it right away. But depending on what went wrong, repairing it could be a better and more affordable option.

A few key factors help in deciding whether to repair or replace your AC compressor. Let’s break them down one by one.

Age of the Compressor

The age of your compressor plays a big role in deciding what makes sense.

Under 10 years old: If your compressor is fairly new and the problem is minor, such as an electrical issue or a bad capacitor, repairing it is usually cost-effective.

Over 10 years: Older compressors tend to develop multiple issues due to wear and tear. In such cases, repairs can pile up quickly and cost almost as much as a replacement.

Extent of Damage

The extent of the damage determines whether a repair is even possible.

Minor issues: Problems like a faulty start relay, a small refrigerant leak, or other external component failures can usually be repaired without replacing the compressor.

Major damage: If the motor is burnt out or the internal parts are badly damaged, the compressor can’t be repaired. At that point, replacement is the only realistic solution.

Cost of Repair vs. Replacement

Comparing the cost of repair to the cost of a new compressor can make your decision easier.

Repair costs: If fixing the compressor is much cheaper than buying a new one, repair is worth considering.

Replacement costs: If the repair bill is close to or higher than the cost of a new compressor, replacement is usually smarter, especially since a new unit will likely run more efficiently and last longer.

Availability of Parts

Finding parts can sometimes be the biggest challenge.

Newer models: Parts for newer compressors are usually easy to find, making repairs simple and affordable.

Older or discontinued models: Parts for older units may be hard to locate or very expensive. In that case, replacing the compressor, or even the entire AC system, might make more sense.

System Compatibility

Your compressor must work well with the rest of your AC system.

Matching capacities: If the system is old or uses a less common compressor size, repairs may not restore full efficiency. It can also be tricky to find a perfect match for your existing setup.

System efficiency: Even if you repair the compressor, an older system might still run less efficiently than a new one. Upgrading to a newer model improves performance and lowers your energy bills.

Refrigerant Type

The type of refrigerant your system uses can also influence your decision.

R-22 refrigerant: Older ACs often use R-22, which is now being phased out due to environmental regulations. Since it’s hard and expensive to find, repairing a compressor that uses R-22 might not be worth it. In such cases, replacing the unit and switching to an R-410A system is usually the better move.

R-410A refrigerant: Newer systems use R-410A, which is more eco-friendly and easier to refill. For these systems, repairs are usually simpler and more affordable.

Overall Condition of the AC System

Your compressor doesn’t work in isolation. Its condition should be evaluated alongside the rest of your system.

Well-maintained system: If the rest of your AC is in good condition, repairing the compressor can be a smart, economical choice.

Worn-out system: If your coils, fans, or other components are also failing, repairing just the compressor won’t solve the bigger problem. In that case, replacing the entire system can save you time, money, and energy in the long term.

Warranty Coverage

Your warranty can make a big difference in your decision.

Still under warranty: If the compressor is covered, the repair or replacement will cost you little to nothing. Repairing it is the obvious choice.

Out of warranty: If the warranty has expired and the repair costs are high, it’s often better to replace the compressor or upgrade to a new, energy-efficient system.

Need Expert Help with Your AC Compressor? Abba HVAC Is Here 24/7

Dealing with a faulty compressor, refrigerant leak, or any issue affecting your air conditioner? Abba HVAC’s licensed technicians are compressor repair specialists, available around the clock across the Greater Austin area. Contact us today for fast, professional service and get your AC back to peak performance!

Step-by-Step Guide to Fix Your AC Compressor

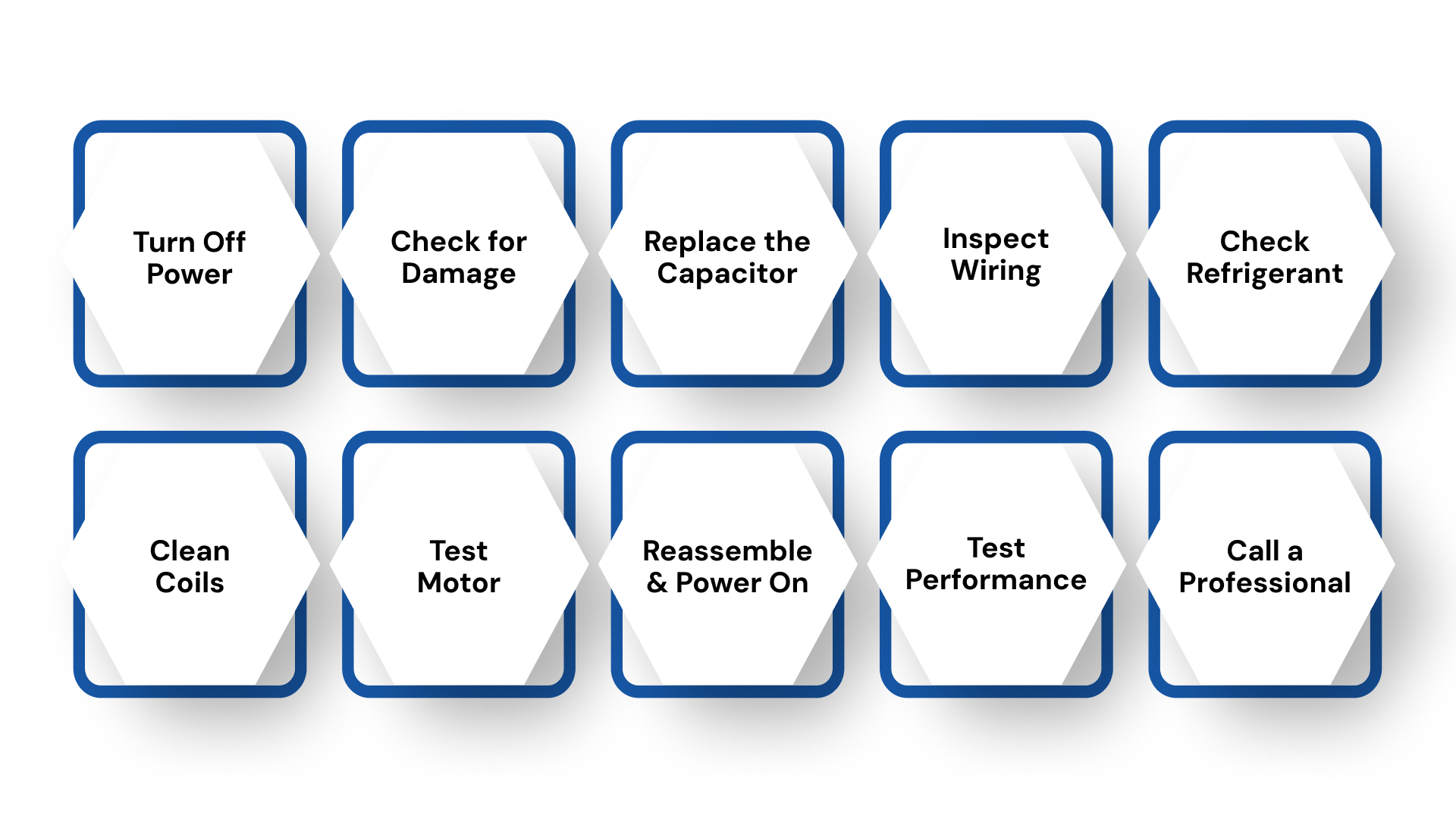

While some compressor problems require a professional’s touch, others you can safely check and fix yourself with the right tools and a bit of care. Here’s a step-by-step guide to help you spot and fix common AC compressor issues.

Turn Off the Power

Before you do anything, ensure safety first. Always switch off the power to your AC unit to avoid electric shocks or accidental starts while you’re working.

Find the power switch near your outdoor unit or switch off the circuit breaker connected to your AC.

Double-check that there’s no electricity flowing to the system before you begin.

Check for Visible Damage

Once the power is off, take a close look at the compressor and nearby components for visible damage.

Burnt wires or loose connections (these often point to electrical issues).

Oil stains around the compressor (these may signal a refrigerant leak).

Cracks, dents, or other damage to the compressor housing.

If you spot any of these, the issue might be serious; best to call a professional.

Inspect and Replace the Capacitor

The capacitor helps the compressor motor start. When it fails, your compressor may not turn on or may run poorly. To check and replace the capacitor, do the following:

Visual check: Look for bulging or leaking on the capacitor.

Testing: Use a multimeter set to measure capacitance. If the readings are off, replace them.

Replace it carefully: Disconnect the old capacitor and fit a new one with the exact specifications.

Inspect Electrical Components and Wiring

Electrical issues are one of the top causes of compressor failure. Check all the wiring for damage or loose connections.

Look for frayed or burnt wires and replace them immediately.

Tighten any loose connections.

Use a multimeter to verify the compressor is receiving the correct voltage.

Check Refrigerant Levels and Leaks

Low refrigerant levels can make your compressor overheat and eventually fail. If your AC isn’t cooling as well as it should, low refrigerant might be the culprit. To check:

Look for leaks: Oily spots or ice buildup around the compressor or evaporator are common signs.

Measure levels: Use a refrigerant gauge to check the system pressure.

If you detect a leak, call a technician. Handling refrigerant safely requires professional tools and training.

Clean the Condenser Coils

When condenser coils get dirty, they can’t release heat properly. This forces your compressor to work harder and increases the risk of overheating. To clean them:

Turn off the power to the unit.

Use a soft brush or vacuum to remove loose dirt and debris.

Apply a coil cleaner to get rid of stubborn grime and rinse with water.

Test the Compressor Motor

The motor drives your compressor. If it’s faulty, your AC simply won’t cool. To test the motor:

Use a multimeter to check for continuity in the motor’s windings.

Listen for unusual noises or failure to start.

If the motor doesn’t respond or makes strange sounds, it might need to be replaced.

Reassemble and Power On the System

Once you’ve finished checking and repairing everything, put all components back in place.

Reconnect all wires, secure the capacitor, and check that refrigerant lines are sealed.

Turn the power back on and set the thermostat to cooling mode to test your system.

Test the System’s Performance

Now it’s time to see if your efforts paid off. Watch how the compressor behaves as the system runs. Look for:

The air should feel cool and consistent.

The unit should cycle normally without short bursts or long pauses.

Listen carefully; any rattling or buzzing could mean something’s still off.

Call a Professional if the Problem Persists

If the compressor still isn’t working after these steps, don’t push it further. Issues like internal motor failure or refrigerant contamination need expert handling. A professional HVAC technician will have the right tools to diagnose and fix the problem safely.

After repairing your AC compressor, following some maintenance tips can extend its lifespan and keep your system running efficiently.

Tips to Make Your AC Compressor Last Longer

Your AC compressor is one of the most essential parts of your air conditioner, and taking good care of it can make it last longer and run more efficiently. A well-maintained compressor can save you from early replacements and expensive repairs. Here are some practical tips to help your AC compressor stay in top shape.

Schedule Regular Professional Maintenance

Schedule annual HVAC tune-ups. Go for a professional inspection and service your AC at least once a year. They’ll clean the coils and ensure everything is working properly by monitoring refrigerant levels and electrical components.

Change Air Filters Regularly

Change your air filters every 1–3 months. In busy seasons like summer, check them each month and replace them if they look dirty or blocked.

Keep the Outdoor Unit Clean and Clear

Regularly clean the area around the uni. Make sure there’s no debris, leaves, or plants blocking airflow. Clean the coils and trim plants to keep air circulating freely.

Check for Refrigerant Leaks and Maintain Proper Levels

Call a professional to check for leaks. If your AC isn’t cooling well or you see ice on the coils, it may be a refrigerant leak. A technician can find the leak, fix it, and refill your system.

Ensure Proper Airflow

Make sure vents and ducts are free from blockages. Clean the condenser coils regularly so dirt and debris don’t block them.

Avoid Overworking the System

Set your thermostat to a comfortable temperature that also saves energy (around 78°F in summer). Don’t turn the AC on and off repeatedly; instead, use a programmable thermostat to manage it better.

How Can Abba HVAC Help You Fix Your Air Conditioner’s Compressor?

A faulty compressor can quickly turn your home uncomfortable, especially during the heat. Addressing the issue early restores your cooling and prevents further damage and expensive repairs. Abba HVAC offers expert AC compressor repair services to get your system running smoothly again, keeping you cool and worry-free all year long.

Why Choose Abba HVAC?

Experienced Technicians for Compressor Repair: Our licensed professionals specialize in accurately and efficiently diagnosing and repairing compressor issues. We ensure your AC is fixed correctly the first time, delivering dependable and long-lasting performance.

Accurate Diagnostics and Transparent Pricing: We believe in honesty and clarity. Before we start, you’ll receive a detailed estimate with no hidden charges or unexpected costs.

Efficient Repair Process: We understand the importance of cooling. That’s why our team works quickly and carefully to complete repairs with minimal disruption to your comfort.

Preventive Maintenance for Longer Compressor Life: Regular maintenance can help you avoid costly repairs later. Our preventive plans keep your compressor in top shape, extending its life and improving your AC’s efficiency.

Local Expertise You Can Trust: Proudly serving Austin and its surrounding areas since 2007, we understand the region’s unique heat challenges and provide tailored repair solutions that truly work.

With Abba HVAC, you get peace of mind. Our expert technicians ensure your compressor runs efficiently, keeping your home cool, comfortable, and energy-efficient year-round.

Final Thoughts

Keeping your AC compressor in good working condition starts with regular maintenance and addressing issues promptly. Warning signs like warm air, unusual noises, or rising energy bills should not be ignored, as they can signal problems that may lead to costly repairs.

Whether you’re a homeowner or a business owner, taking proactive steps to address issues early and maintain your compressor will ensure your AC runs efficiently, keeping you comfortable throughout the year.

At Abba HVAC, we make every service call count. Our licensed technicians use advanced tools and proven methods to ensure your compressor operates at its best, helping you avoid major repairs and extend the life of your system.

Call Abba HVAC today to schedule service, request expert diagnostics, or set up a preventive maintenance plan to keep your system running smoothly all year long.

FAQs

Q1. How do I know if my AC compressor is under warranty?

A1. To find out if your AC compressor is still under warranty, start by checking the paperwork that came with your unit. You can also contact the manufacturer directly. Most AC brands offer warranties that last 5-10 years, depending on the model and its specific terms. Be sure to keep your purchase receipt safe, as it’ll help you quickly verify the warranty.

Q2. Can a dirty AC compressor cause it to fail?

A2. Yes, it can. When dirt and debris accumulate around the compressor, they block airflow, causing the unit to overheat. This extra strain can eventually lead to compressor failure. The best way to avoid this is by keeping up with regular maintenance. Clean the compressor coils and remove any dirt or debris to help your system run smoothly and efficiently.

Q3. Is it possible to repair a seized compressor?

A3. Usually, a seized compressor can’t be repaired. When it seizes up, parts like the motor or pistons often get badly damaged. In most cases, replacing the compressor is the only fix. It’s best to have a technician inspect the unit, as they can assess the extent of the damage and guide you on the next steps.

Q4. How do I prevent my AC compressor from freezing?

A4. A frozen compressor is often a sign of low refrigerant levels, poor airflow, or dirty coils. To prevent this, schedule regular maintenance, check refrigerant levels, clean your filters, and make sure nothing is blocking airflow around the unit. If the compressor keeps freezing up, it’s a good idea to call a technician to find and fix the root cause.

Q5. Does a faulty AC compressor affect the entire HVAC system?

A5. Yes, it does. The compressor plays a key role in moving refrigerant and managing the cooling process. If it fails, the whole HVAC system stops producing cool air. In short, without a working compressor, your AC can’t do its job.