When your HVAC system stops cooling properly or starts making strange sounds, there’s a good chance the compressor is to blame. It works like the engine that keeps your air conditioner running, pushing refrigerant through the system so your home stays cool and comfortable.

According to the U.S. Energy Information Administration (EIA), 42% of U.S. households used electricity as their main heating fuel in 2024, showing how vital reliable, energy-efficient HVAC systems have become.

In this guide, we’ll cover everything you need to know about HVAC compressor replacement, from warning signs and cost factors to professional installation steps and maintenance tips.

Key Highlights

Typical Lifespan: HVAC compressors last 10–15 years with proper care and installation.

Replacement Cost: Expect to spend $1,200–$2,800, depending on size, refrigerant type, and labor.

When to Replace: Warm air, tripped breakers, or loud noises are early signs your compressor is failing.

Repair vs. Replace: If your system is old, inefficient, or out of warranty, a replacement saves more long term.

Trusted Support: Abba HVAC offers licensed, 24/7 service with guaranteed installation quality and long-term energy savings.

What Does an HVAC Compressor Do?

At its core, an HVAC compressor functions like a pump that moves refrigerant through the system, compressing low-pressure gas into a high-pressure, high-temperature state before it’s cooled and cycled again.

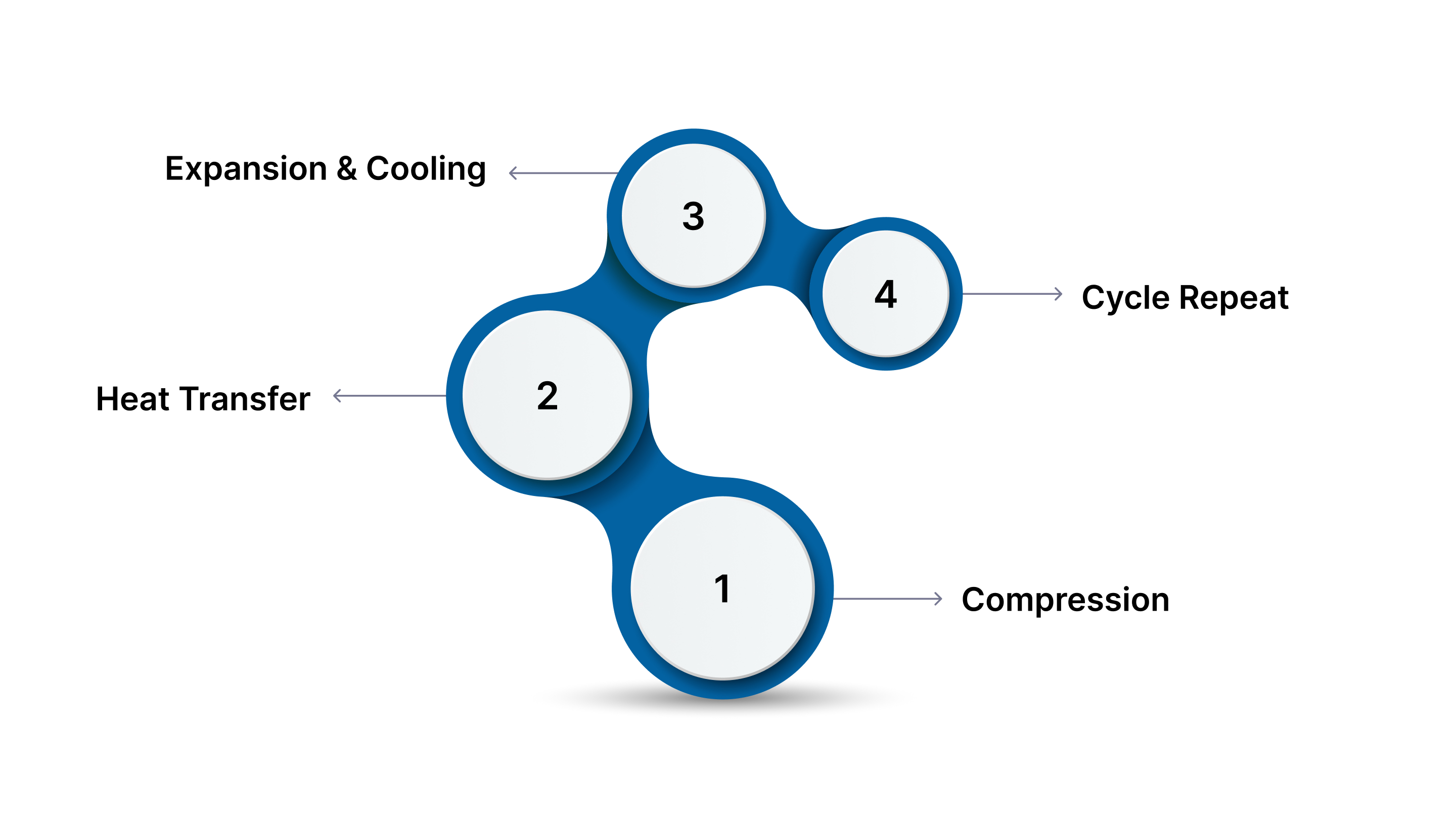

Here’s how it works in simple terms:

Compression: The compressor pressurizes the refrigerant gas.

Heat Transfer: The gas moves to the condenser coil, where it releases heat and becomes a liquid.

Expansion & Cooling: The liquid travels through the evaporator coil, absorbing indoor heat.

Cycle Repeat: The refrigerant returns to the compressor to start again.

Without a functioning compressor, the system can’t circulate refrigerant, meaning no cooling or heating, just wasted energy.

Repair vs. Replace: Which Option Is Right for Your HVAC Compressor?

Deciding whether to repair or replace a failing HVAC compressor isn’t always straightforward. The right choice depends on age, damage type, efficiency goals, and long-term reliability. While repairs can extend the life of your system, replacements often deliver better performance and energy savings over time.

Below is a clear comparison to help you understand when a repair makes sense, and when a full replacement is the smarter investment.

Factor | Repair | Replace |

Cost | More budget-friendly upfront, ideal for newer systems or minor issues. | Higher initial cost but better long-term value through improved efficiency and reduced maintenance. |

System Age | Best for systems under 10 years old that are otherwise in good shape. | Recommended if your system is over 10–12 years old or showing multiple signs of wear. |

Type of Damage | Suitable for issues like wiring faults, capacitor failures, or refrigerant leaks. | Necessary for major failures such as compressor burnout or internal mechanical damage. |

Energy Efficiency | Restores function but may not fully recover lost efficiency. | Upgrades performance and reduces energy bills, especially with newer high-SEER models. |

Warranty Coverage | A good option if your compressor or parts are still under warranty. | The best route if warranty has expired or replacement parts are unavailable. |

Long-Term Reliability | Provides short-term relief but may need repeated service. | Ensures dependable, optimized performance for years with minimal maintenance. |

Once you’ve weighed your options, the next step is understanding what actually happens during a compressor replacement. Knowing the process helps you prepare for technician visits, manage downtime, and ensure the job is done efficiently from start to finish.

What Happens During a Compressor Replacement?

Replacing an HVAC compressor involves more than just swapping out a part; it’s a precise process that ensures the system’s cooling cycle runs safely and efficiently again. Here’s what a typical replacement involves:

System Diagnosis: A certified technician first inspects your system to confirm that the compressor is the true cause of the issue. They check refrigerant levels, electrical connections, and compressor pressure before proceeding.

Recovery of Refrigerant: Before removal, any remaining refrigerant is safely recovered and stored to comply with EPA environmental guidelines. This prevents leaks and ensures safe disposal or reuse.

Disconnecting and Removing the Old Compressor: Technicians disconnect power and detach refrigerant lines and mounting hardware. The damaged compressor is carefully removed to avoid contamination of other system components.

Installing the New Compressor: The new unit is mounted, reconnected to refrigerant lines, and properly sealed. Technicians ensure all fittings and electrical connections meet manufacturer specifications.

System Evacuation and Recharge: The system is vacuumed to remove air and moisture before recharging with refrigerant at precise levels for optimal performance.

Testing and Quality Check: The technician runs a full performance test, monitoring pressure, temperature, and current draw, to ensure the new compressor operates smoothly and efficiently.

Final Inspection and Documentation: Before wrapping up, you’ll receive a summary of the work done, warranty details, and maintenance recommendations to extend the compressor’s lifespan.

Understanding the True Cost of HVAC Compressor Replacement

The cost of replacing an HVAC compressor can vary widely depending on your system type, brand, and labor rates in your area. On average, homeowners can expect to spend between $800 and $3,000, including both parts and professional installation.

Here’s a closer look at the main factors that influence the total cost:

Compressor Type: Scroll and variable-speed compressors are typically more expensive than reciprocating models due to their higher efficiency and advanced technology.

System Size and Capacity: Larger HVAC systems require more powerful compressors, which can increase material and labor costs.

Brand and Model: Premium brands may come with higher part costs but often include better warranties and durability.

Refrigerant Type: Systems using R-410A or newer refrigerants may cost slightly more due to current supply and environmental standards.

Labor and Installation Complexity: Accessibility, refrigerant recovery, and electrical work can all affect labor time and cost.

Warranty Coverage: If your compressor is still under manufacturer warranty, you may only need to pay for labor instead of the entire replacement cost.

Pro Tip: Regular tune-ups and timely refrigerant checks can help avoid compressor burnout, one of the most expensive HVAC failures to fix. |

For example, replacing a 3-ton central AC compressor in a standard residential system might cost around $1,800 to $2,200, while a variable-speed unit in a high-efficiency system could reach $3,000 or more. If your system is still under warranty, that cost can drop significantly, often to just the price of labor and refrigerant handling.

Signs Your HVAC Compressor Needs Replacement

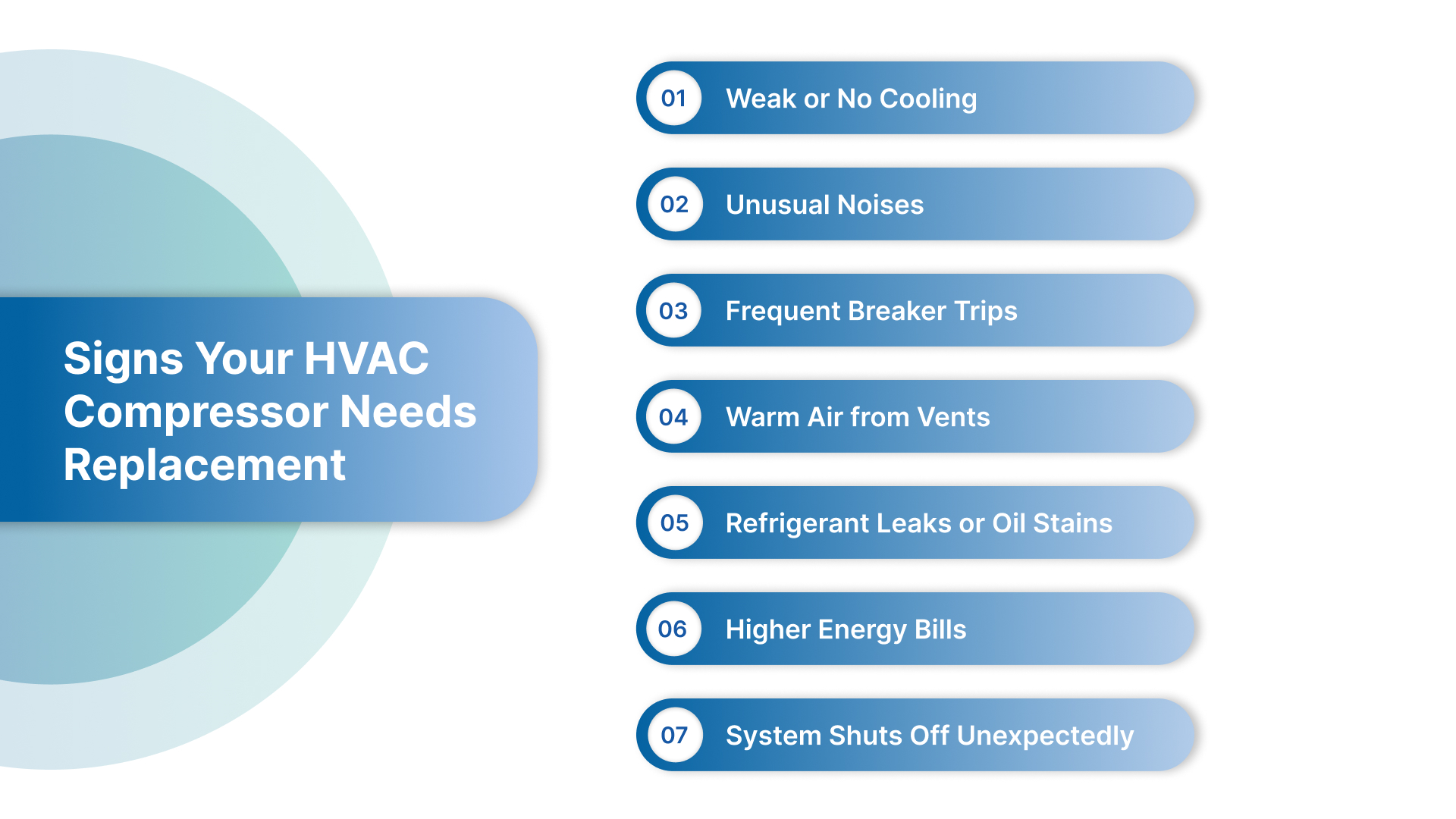

Your HVAC compressor rarely fails overnight; it usually gives several warning signs before breaking down completely. Recognizing these early can help you act quickly and avoid expensive system damage.

Here are the most common signs that your compressor may need replacement:

Weak or No Cooling: If your air conditioner is running but not producing enough cool air, the compressor may be losing its ability to pressurize refrigerant properly.

Unusual Noises: Grinding, clanking, or hissing sounds from the outdoor unit often indicate internal component damage or motor failure.

Hard Starting or Frequent Breaker Trips: A compressor that struggles to start or frequently trips your circuit breaker is likely drawing excessive power, a sign of mechanical failure or electrical shorting.

Warm Air from Vents: When the compressor isn’t working efficiently, it can’t circulate refrigerant effectively, resulting in warm air even when the system is set to cool.

Refrigerant Leaks or Oil Stains: Visible oil spots near the condenser or refrigerant lines often point to a compressor seal or valve issue.

Higher Energy Bills: A failing compressor must work harder to maintain desired temperatures, which increases your energy consumption.

System Shuts Off Unexpectedly: If the outdoor unit frequently stops running or doesn’t turn on, the compressor may be overheating or seized.

NOTE: If you notice two or more of these symptoms, schedule a professional inspection before the problem escalates into a full system replacement. |

Once you start noticing these symptoms, timing becomes everything. Acting early can prevent a complete system breakdown and save you from an unexpected replacement.

But even with professional help, some homeowners make avoidable mistakes during installation that can compromise performance or shorten the new compressor’s lifespan.

Common Mistakes to Avoid During HVAC Compressor Replacement

Replacing an HVAC compressor is a technical process that requires precision and experience. Even small missteps during installation can affect performance, void warranties, or cause early failure. Below are common mistakes to avoid, and why they matter.

Skipping a System Flush: Residual debris or moisture in the refrigerant lines can contaminate the new compressor. Always ensure your technician performs a full system flush before installation.

Reusing Old Refrigerant or Filter Drier: Using old refrigerant or failing to replace the filter drier can allow contaminants to circulate, damaging the new compressor over time.

Incorrect Refrigerant Charge: Overcharging or undercharging the system affects pressure balance, which can lead to poor cooling performance or compressor burnout.

Improper Electrical Connections: Loose or mismatched wiring can cause voltage irregularities, tripping breakers, or permanent compressor damage.

Ignoring Manufacturer Specifications: Each compressor model has unique installation requirements. Skipping torque checks, incorrect mounting, or using non-approved components can void warranties.

Not Addressing Root Causes: Replacing the compressor without fixing underlying issues, such as dirty coils, blocked airflow, or refrigerant leaks, only delays future breakdowns.

Always work with certified HVAC professionals like Abba HVAC who follow EPA and manufacturer guidelines to ensure safe, lasting performance.

Why Homeowners Trust Abba HVAC for Expert Compressor Replacement?

Choosing the right contractor for your HVAC compressor replacement is just as crucial as selecting the compressor itself. A reliable installer ensures proper setup, maximum system efficiency, and long-term reliability. That’s why partnering with a licensed, local, and experienced team like Abba HVAC makes all the difference.

Here’s why they’re the right fit for the job:

Licensed & Insured: Operating since 2007, Abba HVAC holds all the necessary Texas licenses and insurance, ensuring every installation meets professional and safety standards.

Local Expertise: Based in Greater Austin, Abba’s technicians understand Texas weather demands, from extreme summer heat to unpredictable humidity.

24/7 Availability: HVAC failures can strike anytime. Abba HVAC’s emergency response team is available around the clock to restore comfort fast.

Comprehensive Services: Beyond compressor replacement, they handle HVAC installation, plumbing, and electrical support, making them a one-stop solution for home and commercial systems.

Experienced Leadership: With over 20 years in HVAC and construction, their leadership ensures every project is handled with precision and care.

Energy Efficiency Commitment: Abba HVAC focuses on installing energy-efficient components that enhance comfort, lower bills, and extend your system’s lifespan.

Don’t just take our word for it, read what our customers have to say about their experience with Abba HVAC:

“These guys are the real deal. Abba HVAC has been taking care of our office building for three years, and honestly? I sleep better knowing they're on it. Their maintenance program has saved us a fortune in emergency calls.”

– David R., Commercial Property Manager“Abba HVAC installed our smart thermostat and it's been amazing. The energy savings are real, our bills dropped 20% the first month. Their team knows Austin's climate challenges inside and out.”

– Sarah M., Homeowner, Cedar Park

Benefits of Professional HVAC Compressor Replacement

A professional HVAC compressor replacement isn’t just about swapping a part; it’s about restoring your system’s performance, efficiency, and reliability. When handled by certified experts, the process ensures long-term comfort and lower repair risks.

Here’s what you gain from professional replacement:

Improved System Efficiency: A properly installed compressor optimizes refrigerant flow and pressure, reducing energy use and keeping cooling consistent.

Extended Equipment Lifespan: Correct installation and system calibration prevent strain on other HVAC components, helping your unit last longer.

Warranty Protection: Certified replacements comply with manufacturer guidelines, keeping your warranty valid and safeguarding your investment.

Enhanced Cooling Performance: A new compressor restores full cooling capacity, ensuring your home maintains steady, comfortable temperatures.

Lower Long-Term Costs: Prevents recurring issues caused by improper installation or mismatched components, saving money on future repairs.

Peace of Mind: Knowing the work meets safety, efficiency, and regulatory standards offers long-term confidence in your HVAC system.

Final Words

A failing compressor doesn’t just impact cooling, it affects your home’s overall comfort, energy efficiency, and long-term system health. Timely replacement by certified professionals ensures your HVAC unit operates at peak performance while preventing future breakdowns.

Whether you’re noticing reduced cooling power, rising energy bills, or unusual system noises, addressing compressor issues early can save you significant time and money in the long run.

Want to restore your HVAC system’s efficiency? Contact Abba HVAC today for reliable compressor replacement, expert diagnostics, and long-term comfort solutions, available 24/7 across Greater Austin and surrounding areas.

FAQs

1. How much does it cost to replace an HVAC compressor?

The average cost ranges from $1,200 to $2,800, depending on your system’s size, refrigerant type, accessibility, and labor rates. High-efficiency or speciality units can cost more.

2. How long should an HVAC compressor last?

With regular maintenance, most compressors last 10–15 years. Factors like improper installation, poor ventilation, or refrigerant issues can shorten their lifespan.

3. Can I replace just the compressor instead of the whole system?

Yes, but only if the rest of the system is in good condition and uses the same refrigerant type. For older units, replacing the entire system is often more cost-effective in the long run.

4. What are the main signs that my compressor is failing?

Common signs include warm air from vents, frequent breaker trips, grinding noises, or visible refrigerant leaks. These usually indicate the compressor is under strain or near failure.

5. Is it worth repairing a broken HVAC compressor?

If your unit is still under warranty or less than 10 years old, repair might make sense. Otherwise, replacement is typically more efficient and provides better long-term reliability.